In the commune of Saint Gilles, Brussels, exists a brewery that was established on an idea that goes beyond the conventional brewery encounter. With “Our Brewery is Yours” as a motto to live by, the team at Beerstorming placed not only the beer, but also the craft into the hands of its customers. Beyond this, they also claim to have brewed Belgium’s very first carbon neutral beer. I sat down with co-founder and manager, Arthur Ries to discuss their unique approach to brewing, as well as the brewery’s strides toward being a sustainable outfit.

Let us start with how it works. Arthur describes the brewery as a laboratory: a space for people to collaborate and experiment to create beers that they want to drink. At Beerstorming, two or three sessions commence each week where paying customers enter the lab to engage in a collaborative exchange of ideas, select ingredients for their recipe, and ultimately craft their own unique beer. It may be expected that the guidance of a master brewer may place restrictions on the creative process… surely some beers are just too crazy, no? For the most part, no. In English we use the idiom “a man after my own heart” to refer to a person that has similar beliefs, values, or preferences as ourselves. Arthur is a man after my own heart. He is always chasing the next new beer, the next novel taste. Through this belief, Beerstorming loves taking the “crazy” ideas of their clientele, and utilising their own expertise to guide them into reality.

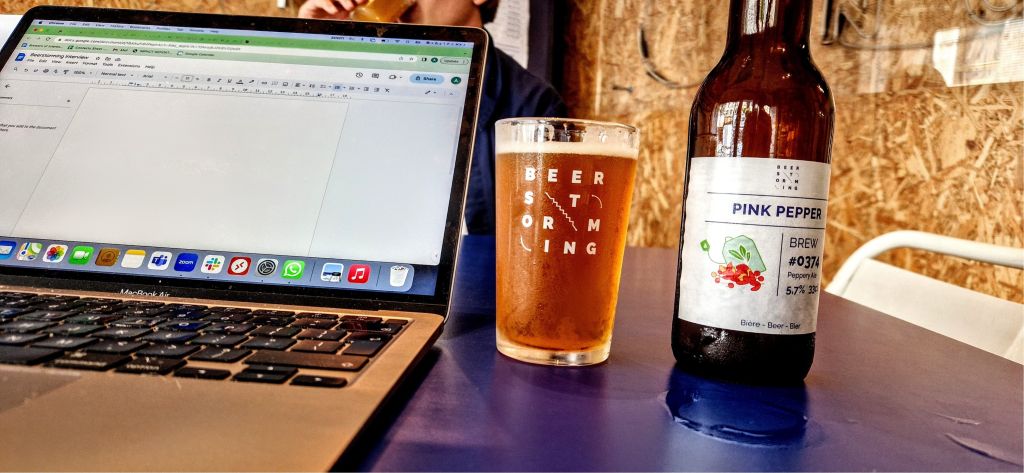

The creations brewed by the people who enter Beerstorming’s brewery commonly find their way to the taps that are found in close proximity to the brewing space. This taproom is open four days a week to allow those who venture in to taste these customer-driven brews. Every quarter, the beers brewed in that three month period are put to a vote on social media. The five beers with the most votes get submitted to a jury that chooses the best. This recipe is then brewed in mass production and put on the market as a Beerstorming beer.

Anybody who has seen Beerstorming’s brewery with their own eyes will know exactly why they refer to themselves as a pico-brewery. Arthur joked that there probably is not a word to describe the size of this establishment. The brewery itself has a capacity to brew around 75-80 litres of beer in a single batch. Thus, Beerstorming partners with various breweries who have a larger brewing facility who offer their tanks to mass produce the beers that win the vote of the jury.

To some, the notion of a brewery where its entire beer production is determined almost solely by its customer base might appear like a novelty. To be honest, it is. It is highly unusual. As Arthur laughed, Beerstorming has no idea which beer will be their next. There is some genius behind the idea; Beerstorming is directly brewing the beers that its own customers want to see on the market. Sure, not every beer is for everyone’s taste. But with five taps in rotation and eight mass produced beers on the market, everyone is sure to find a beer to their taste here. At the time of speaking, Beerstorming had brewed 536 different beers during its existence.

“Our Brewery Is Yours”

However, there is more to this idea than business; the whole concept is beautifully social. Beer should first and foremost bring people together. Picture Oktoberfest, where the sprawling tents and communal tables beckon people of all ages, backgrounds, and nationalities to take a seat and raise their steins in unison. Beerstorming embraces that same spirit in a ‘pico’ format and brew. What is more socially sustainable than to allow your customer base to shape the destiny of new beer recipes? “If I want to brew a gose IPA tomorrow I can. But that’s not really my philosophy, I like to brew what the people want”. Behind every beer lies a story and the inspiration to brew a beer for the people, by the people.

“Let’s create a place where people can learn about beer”

The laboratory, as Arthur refers to it, also offers a space for people to learn about the tipple they savour. Patrons of Beerstorming range in experience, from homebrewers to complete novices. This does not stop the team at the brewery guiding anyone who wishes to brew a beer to brew one. As someone who writes about sustainable projects that exist within the beer sector, I commend the work Beerstorming is undertaking. To understand the brewing process and the ingredients that a beer is composed of is to begin to understand and appreciate the resource intensity that is behind beer production. When customers leave the doors of Beerstorming, they leave better educated consumers.

This is something the brewers are very aware of too. Beyond their social side, Beerstorming is committed to being as sustainable as it can. Arthur detailed how this has always been the intention from the outset: “it is best to implement this from the start, than to get to five years and start trying”. Because of Beerstorming’s frequent interactions with the public who enter their laboratory to brew, the brewers also have the opportunity to teach people about the sustainability impacts of the sector. Arthur noted this is something they do not shy away from. Nonetheless, as referenced in the introduction, their headline achievement is brewing the first carbon neutral beer in Belgium*.

*Caveat: Beerstorming is very transparent about the fact that this beer did require some offsetting in order to be labelled as such. In the climate policy realm this is an ever more important discussion, as to whether offsetting should be considered credible enough to bolster a claim of carbon neutrality. What I will say is this, my conversation with Arthur did make clear that Beerstorming reduced their emissions as much as they could before offsetting the remainder of their emissions was considered.

“We know we are not at zero with our CO₂ but clearly that is the goal”

Partnering with CO2logic, the brewery first assessed the footprint of one of its beers, #0028 GMGK, and began to tackle the areas they considered possible to improve on. GMGK’s assessment concluded that the beer was emitting around 3.6kg of CO₂ per litre brewed. To calculate this figure, similar assessments are required for all suppliers in Beerstorming’s supply chain. Where suppliers had not calculated this for themselves, CO2logic and Beerstorming needed to calculate the figures for them. The calculations alone took around 18 months to finalise. Then came the step to reduce this 3.6 figure. Beerstorming undertook practices such as purchasing renewables from energy suppliers in the city, switching to electric vehicles and promoting the use of reusable growlers in the taproom. After these steps and more, Beerstorming reduced the footprint of GMGK to 2.4kg of CO₂ per litre brewed.

Arthur spoke with conviction about the Belgian beer sector and its necessity to improve its ecological impact. He not only recognised the steps that Beerstorming needs to take in the future, but also welcomed the desire of other brewers to do better with their production. For now, there are some obstacles that Beerstorming will not be able to counter. For example, whilst they utilise many local products, the brewers also do not wish to forgo the use of American hops – the transportation and energy-intensive processes involved in their importation certainly adds to their footprint. Equally, a brewery of this size and scale struggles to implement measures that larger breweries find easier, such as recapturing its CO₂.

This is why Beerstorming is only at the beginning of its journey. As the brewery grows, the co-founders want to build their own, bigger brewery where, once again, they can implement sustainability from the very start. This vision includes the installation of solar panels to produce their own electricity to fuel their brewery.

Another aspect I was keen to delve into was Beerstorming’s potential for waste beer. Whilst the concept behind the brewery is undeniably appealing, and I do not doubt the brewers’ expertise in guiding the process, I was convinced that too often a beer would not be drinkable. However, out of the 536 beers brewed, Arthur noted only four had to be entirely trashed – and not always due to the concept (sometimes brewers simply make mistakes, right?). Nevertheless, Beerstorming are open about this aspect of their brewery too: “not all of our beers are the best beers, we know that”. Generally, the 80 litres produced stay on tap for around two weeks, but some stay longer than others depending on its reception in the bar. Still, the majority of their beer gets drunk at the taproom by customers. For those slightly less-quality beers, Arthur ensures me he “always has friends willing to drink it” – the best waste prevention tactic in my eyes.

On the topic of waste, one easily implementable circular waste practice is to direct spent grains to a new life after the brewing process. Most brewers cooperate with local farmers who utilise what is known as brewer’s spent grain (BSG) in animal feed or composting. Beerstorming too works with a local farm in the same vein. However, they have also experimented a lot with the BSG, with projects including the drying and milling of their grains to produce flour, working with Belgian restaurants who have utilised the grains to bread their snacks such as croquette/kroket or frikandel, and circular projects that allow the reuse of pellets both in brewing and in bread making. Similarly, Beerstorming was previously contacted by engineering students who wished to experiment using the BSG for the production of particleboard furniture. These innovative collaborations encapsulate the creativity and openness to experimentation that exists here.

What I like most about this brewery is that it is an ode to the limitless possibilities that lie within a beer glass. Whether a novice or connoisseur, Beerstorming beckons to the inner brewmaster in everyone. Here the team have designed a concept that transcends the traditional brewery experience, through a fusion of creativity, companionship, and craft. Beerstorming’s commitment to not only teach the public about beer, but learn from them too is admirable. Whilst I applaud their efforts toward being an ecologically sustainable brewery, my hat really goes off to how social this establishment is. The two aspects in unison will take this brewery to amazing places in the future.

What is your favourite beer that Beerstorming has brewed?

It is no shock that this was not an original question conjured by myself – Arthur is asked this question on a probably too frequent basis. However, the night prior he had been drinking with a friend an old beer produced at the brewery, named Stout Morning that had utilised yeast from sourdough provided by a local bakery. A very light, slightly acidic and easy drinking stout in Arthur’s words: one he felt was a memorable beer.

Where can you buy Beerstorming’s beers and how can you brew there?

All of Beerstorming’s mass produced beers and “crazy” 80 litre batches can be purchased directly at the building that acts as a shop, brewery and taproom all in one. You can find them located at Chaussée d’Alsemberg 75, 1060 Saint-Gilles. Throughout the summer, you can also find Beerstorming’s stand at the Marché de Saint-Gilles on Mondays at Place van Meenen. Additionally, Beerstorming’s bottled beers can be purchased at these locations as well as online at My Beer Box. All details about their tastings, classes and brewing sessions can be found here.